Add 1% ~ 3% stearic acid as lubricant for molding. Metal chromium powder carbonization method carbon black according to the ratio of 13.5% ~ 64% (mass) (more than the theoretical combined carbon 11.33%) and electrolytic chromium are crushed to form 325 metal chromium powder, which is dry mixed with a ball mill and used as raw material. Used to produce anti-wear films and semiconductor films. A large number of thermal spraying materials are used as metal surface protection processes. The welding rod made of it and surfacing welding on the working surface of some mechanical equipment (such as coal mill, ball mill, Hubei plate, etc.) can increase the service life by more than several times. It can be used as an additive for welding materials. it can be used as an additive for cemented carbide (such as tungsten carbide-based cemented carbide grain refiner), thus being applied to mining, mechanical processing, etc. The combustion products are divided into upper and lower layers, and the lower layer is cast chromium carbide (Cr3C2).ġ. When the temperature of the tungsten coil rises to 1500 ℃, the material is ignited and starts to burn, and the combustion wave spreads downward until the reaction ends. Spontaneous propagation high-temperature synthesis method combines Cr2O3,CrO3,Al powder and carbon black with a ratio of 1:0.73:0.73:0.25, puts the prepared raw materials into a mixer and mixes for 6 hours, puts the mixed materials into a graphite crucible, compacts in a reactor, uses Ar as medium, and preforces the pressure to be 5MPa, ignition with the upper plane ignition source of the tungsten wire ring. Preparation by carbothermal reduction method: there are two reaction mechanisms. (4) After the crushing and carbonization is completed, the power will naturally cool down and continue to vacuum until the furnace temperature drops below 300 ℃ to stop the pump and destroy the vacuum. At this time, the heating rate is generally about 10 ℃/h, and the constant temperature starts when the furnace temperature rises to 1450 ℃, and the constant temperature time is 10h.

CHROMIUM MELTING POINT FULL

When the furnace temperature rises to 300 ℃, the input power increases to 80%, and the furnace temperature rises to 800 ℃ and uses full power to raise the temperature. The input power at the beginning is determined as the 50% of all input power depending on the burning loss of the heating element. When the pressure in the furnace is less than 30Pa, power transmission can be used to raise the temperature. Vacuum should be pumped before power transmission. (3) The carbonization equipment is a 0.15MVA vacuum resistance furnace. The formed material block should be handled with care, dried naturally for 48 hours, put into a drying oven for drying, the drying temperature is 110☑0 ℃, the temperature is kept for 10 hours, the temperature is raised to 300 ℃, and the temperature is kept for 10 hours. The size of the material block is Φ φ90 × 60mm, and each piece weighs about 2.5kg.

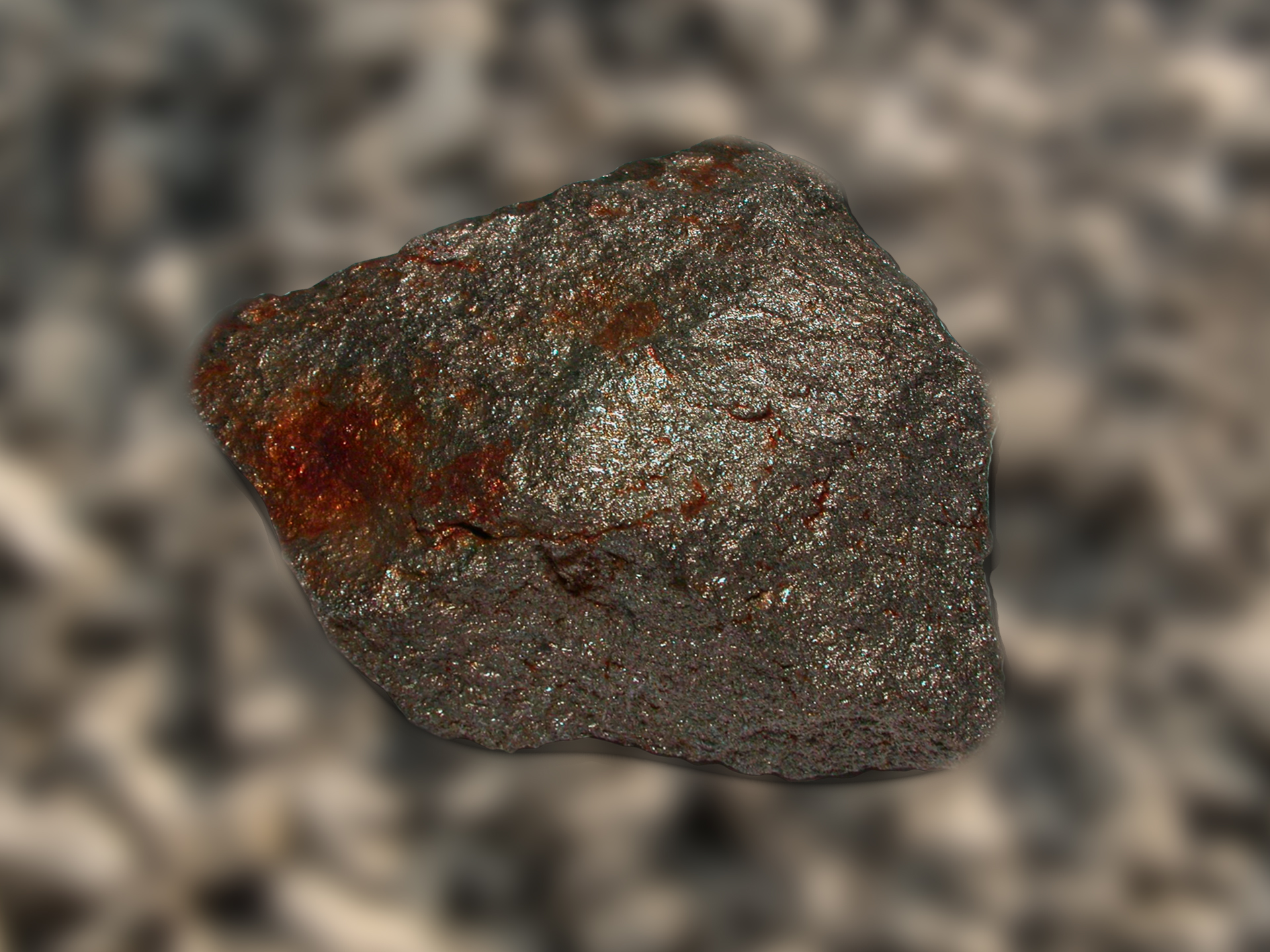

The mixing time is 20~30min, and the rotation direction of the mixing barrel is changed every 5min. The volume of feeding should account for 1/3~2/5 of the volume of the mixing barrel. The feeding sequence is to add graphite powder first, then metal chromium powder, and then paste. (1) Mixing The weighed raw materials are added into the electric mixing barrel. The ratio of raw materials is: metal chromium powder: graphite powder: binder = 86.5:13.5:3.5. 1 shows the process flow of chromium carbide powder production, in which the carbonization temperature is 1450 ℃ ~ 1500 ℃ and the diffusion time is 45min. chromium carbide is produced by the following process flow. Gray powder with metallic luster Rhombic crystal system Density: 6.68g/cm3 Melting point: 1890 ℃ It has good wear resistance, corrosion resistance and oxidation resistance in high temperature environment (1000~1100 ℃). Because of its special high temperature performance, it is widely used as a thermal spray material for metal surface protection process and an additive in the cemented carbide industry. Information provided by: (external link)Ĭhromium carbide is an inorganic material with high melting point and good wear resistance, corrosion resistance and oxidation resistance under high temperature environment (1000~1100 ℃).

0 kommentar(er)

0 kommentar(er)